Rapid Deployment Modular Hospitals: A Strategic Guide for Turnkey Medical Camp Solutions

From the recurring waves of COVID-19 to Ebola containment in remote regions, or the urgent need for Cholera treatment centers in post-earthquake zones, the message is clear: global healthcare Infrastructure is stuck in a bottleneck.

For Government Medical Projects and NGO Medical Infrastructure planners, the traditional 12-to-36-month construction cycle is a systemic failure when facing a critical Pandemic Response. Procurement teams can no longer afford to wait years while urgent needs at a Refugee Medical Camp or a Disaster Relief Hospital go unmet.

SOEASY are shifting the paradigm from "construction" to "assembly." As a specialized Turnkey Medical Camp Solution provider, we leverage Prefabricated Hospital and Modular Medical Building systems to compress project timelines by 50%–70%. Whether you need a temporary Field Hospital or a permanent facility, we deliver medical-grade solutions in weeks rather than years.

1.Why Top Procurement Officers Choose Our Hybrid Camp System

Clients typically face a dilemma: they need high-performance medical zones but have a limited budget for general Accommodation. We solve this by deploying a strategic "Hybrid Ecosystem" that combines two distinct prefabrication technologies:

For Critical Medical Zones (The Flat Pack Advantage): For core functional areas like ICUs, Operating Theaters, and Isolation Wards, we deploy our Flat Pack Container Hospital System. These units offer superior structural strength and high airtightness, which is crucial for maintaining Negative Pressure environments and strict infection control.

For Support & Living Zones (The T-House Advantage): For large-scale non-clinical areas such as Medical Staff Dormitories, Canteens, and Warehouses, we utilize the Prefab T-House System. This light steel structure offers a significantly optimized cost-per-square-meter while providing flexible, large-span spaces essential for comfortable living and logistics.

A comprehensive Turnkey Medical Camp Solution that delivers Medical Grade safety where it counts, while maximizing your project's ROI (Return on Investment) on general infrastructure.

2.Engineered for Medical Excellence: The Material Science

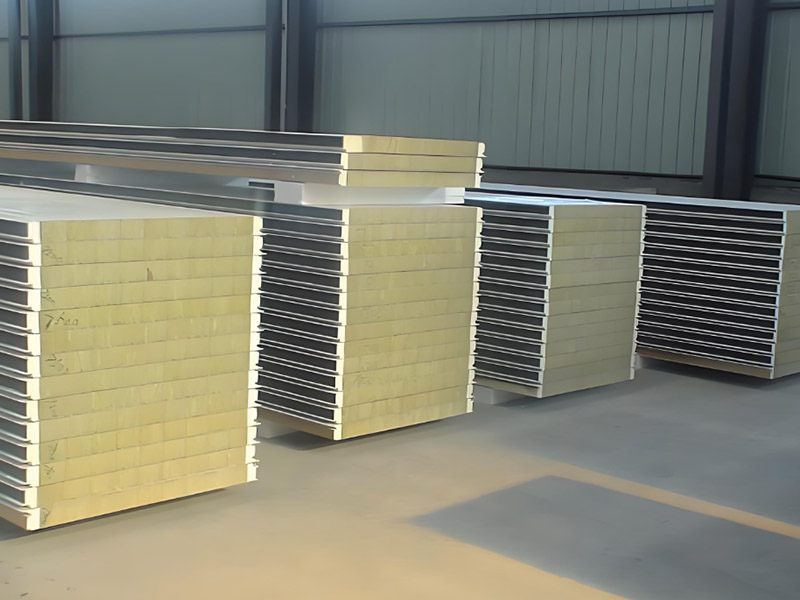

We move beyond standard prefabrication by customizing the wall system to match the specific clinical function of each room. Here is the technical breakdown of our medical-grade envelope:

A.Infection Control: The "Clean Room" Standard

For Operating Theaters and Isolation Wards, surface integrity is critical. We utilize Purified Sandwich Panels engineered with an Antibacterial & Antistatic coating. This prevents microbial attachment and repels dust accumulation.

Panels are joined with a flush, hermetic interface. This structural airtightness is the only way to guarantee the Negative Pressure required to contain airborne pathogens.

SOEASY don't believe in "one size fits all." As shown in our material lineup, we specify the core based on your project's environment:

-Rock Wool: Our default specification for A-Level Fire Resistance and thermal insulation.

-Aluminum Honeycomb: Specified for ceilings requiring superior flatness and high rigidity over large spans.

-Magnesium Oxide/Sulfate: The heavy-duty choice for extreme durability and moisture resistance, ideal for humid tropical climates.

B.Radiation Safety: Integrated Lead Shielding

Standard container walls offer zero protection against ionizing radiation. For CT and X-ray rooms, we manufacture a custom Radiation Shielding Panel.

SOEASY laminate a High-Density Lead Composite layer (or pure lead sheet) directly between the structural boards during factory production.

High atomic number lead effectively attenuates X-rays and Gamma rays. This integrated design ensures your facility meets international Radiological Safety Standards without needing messy post-installation retrofits.

C.MRI Precision: Electromagnetic Isolation

MRI equipment is notoriously sensitive to external interference. To counter this, we employ Magnetic Shielding solutions using High-Permeability Alloys (like Silicon Steel or -µ metal).. This construction creates a "Faraday Cage" effect, ensuring image clarity by isolating the machine from the surrounding electronic noise of the camp.

3. Global Project Spotlight: Scalable Solutions in Action

To demonstrate our versatility, we share three recent case studies ranging from remote clinics to comprehensive medical complexes. These projects highlight how we solve logistical hurdles and deliver turnkey results.

Case A: Small Scale – The Remote Island Clinic (Philippines)

Project Profile: Rural Community Healthcare Outpost

Timeline: August 2025 (Deployed in 14 Days)

A localized government unit needed a functional clinic for a remote island community accessible only by small barges. Concrete construction was logistically impossible due to the lack of raw materials and heavy machinery.

SOEASY deployed our Modular Community Clinic layout. The design features a compact footprint containing two distinct clinic rooms, an Equip. Sterilize room, and a Nurse Station.

The client was concerned about future population growth. We engineered the structure with a "Future Add-on" interface, specifically designating space on the first floor for a General Storage and Pharmacy expansion.

A fully functional outpost delivered in standard shipping containers, assembled without heavy cranes, providing immediate primary care.

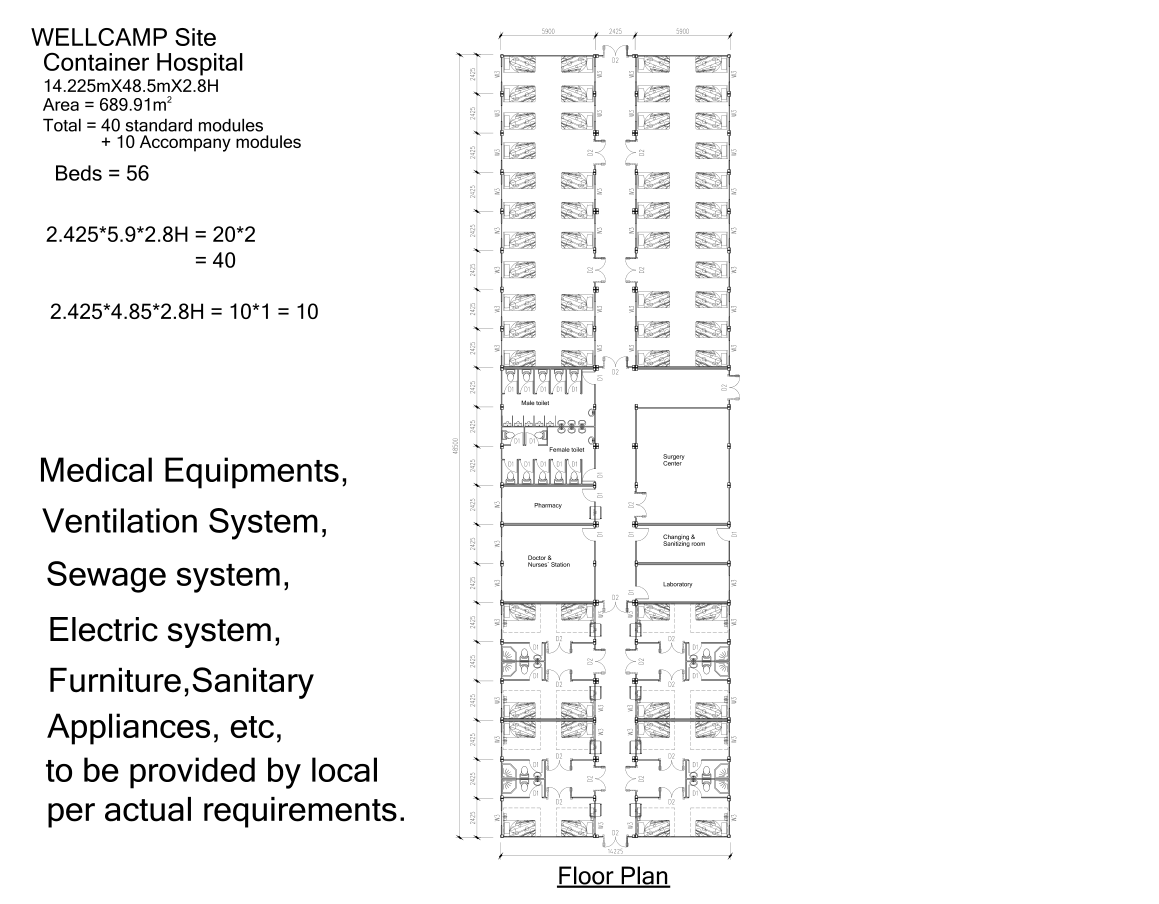

Case B: Medium Scale – Mining Camp Inpatient Ward (DRC)

Project Profile: 50-Bed Field Container Hospital for Industrial Site

Timeline: January 2025

A Copper Mining Company in the Democratic Republic of Congo faced a malaria outbreak. They urgently needed to upgrade from temporary tents to a hygienic, climate-controlled inpatient facility. The site was narrow and uneven.

SOEASY utilized our 50-Bed Container Hospital design. With dimensions of 14.2m x 48.5m, the linear layout fits perfectly on restricted sites.

To maximize bed capacity without overcrowding, we optimized the layout to fit 56 beds by creating dual wings. The challenge was incorporating surgical capabilities in such a dense layout. We integrated a central Surgery Center and Laboratory directly between the male and female wards, creating a centralized "clean zone" for efficiency.

A rugged, semi-permanent facility capable of handling high patient volume, providing safe Male and Female toilets and dedicated nursing stations.

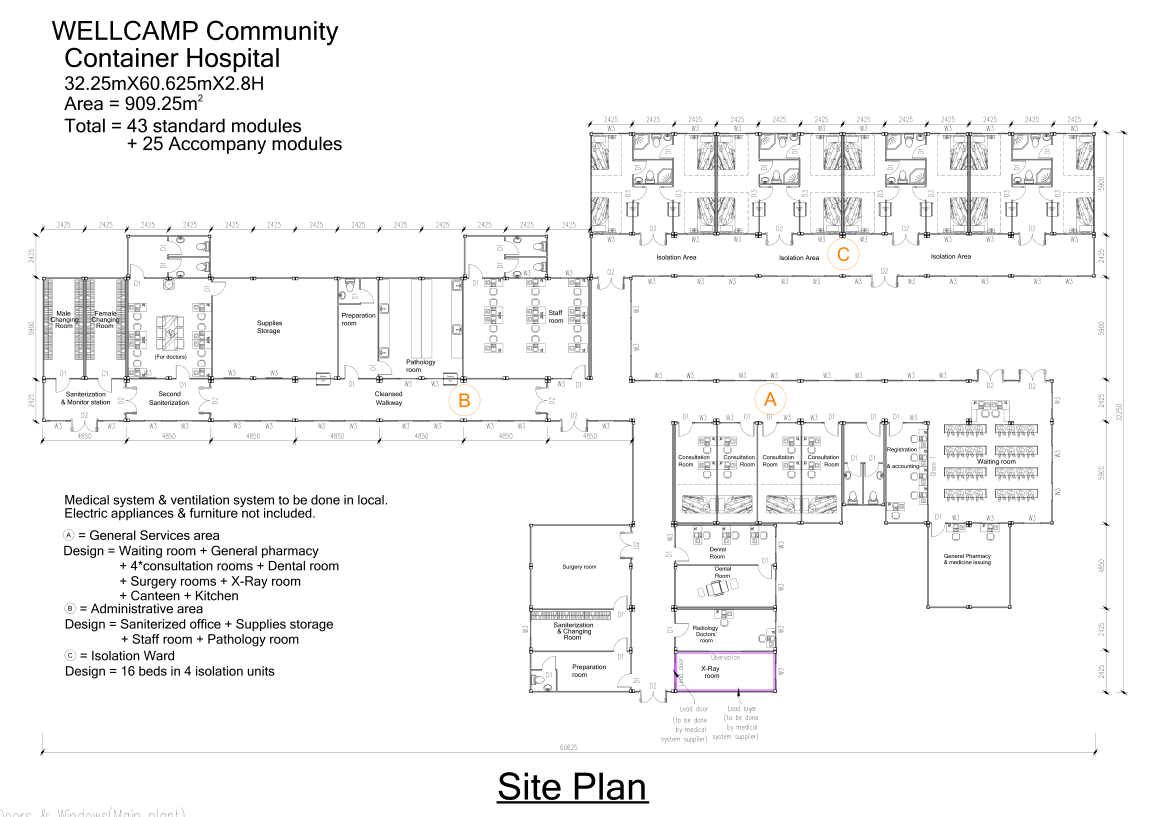

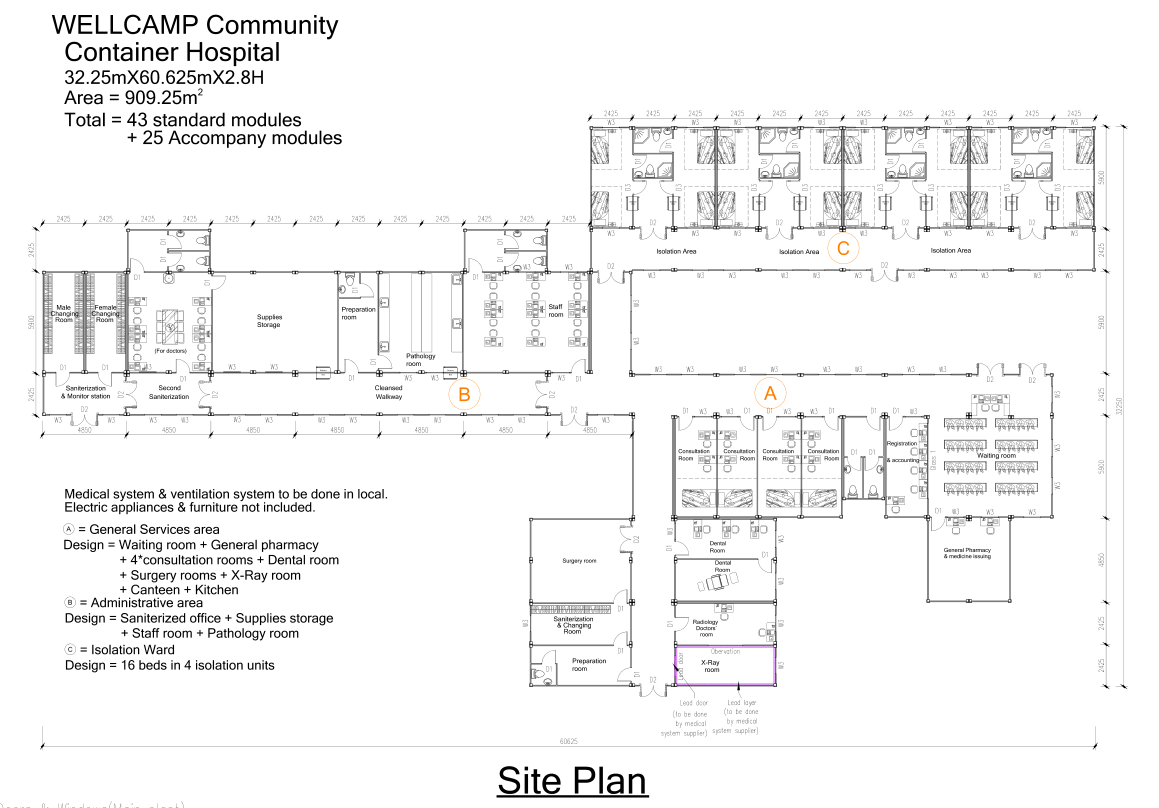

Case C: Large Scale – Municipal General Hospital (Argentina)

Project Profile: 909m² Comprehensive Medical Complex

Timeline: Completed Late 2026

A municipality needed to replace an aging facility to serve 20,000+ residents. They required a full-service hospital with imaging and isolation capabilities but had a strict 6-month deadline.

SOEASY deployed our flagship 909.25m² Community Container Hospital. This complex assembly used 43 standard modules connected by 25 accompany modules to create wide, hospital-grade corridors.

The main hurdle was Radiation Safety and Infection Control.

For the X-Ray room, we designed the walls to accommodate a Lead layer and specified a 1200x2000mm Lead door, ensuring full compliance with local safety laws.

SOEASY strictly zoned the facility into three areas: General Services (Dental/Surgery), Administrative (Offices), and a specialized Isolation Ward. The isolation zone features 16 beds in 4 independent units, effectively stopping cross-contamination.

A landmark project delivered months ahead of schedule, proving that Modular Construction can deliver complex, multi-departmental medical layouts indistinguishable from permanent structures.

4. Engineering Solutions to Critical Infrastructure Challenges

Based on the case studies above, we have standardized our technical response to the three most common barriers in medical construction:

Challenge A: The "Last Mile" Logistics Barrier

As seen in the Island Clinic project, remote sites often lack the heavy lifting machinery (cranes) and road infrastructure required for traditional construction or modified shipping containers.

SOEASY utilize a Flat Pack Container House & Detachable Container House System. All components are modular and lightweight enough to be transported by small trucks or barges. The structural assembly relies on high-strength bolted connections rather than onsite welding, allowing for manual installation by semi-skilled labor without heavy equipment.

Challenge B: Site Constraints vs. Capacity Demands

In the Mining Camp project, the client needed high bed density (50+ beds) on a narrow, irregular strip of land, while maintaining strict separation between infected and healthy zones.

SOEASY employ Linear Layout Optimization. Unlike rigid fixed structures, our modules can be linked longitudinally to fit narrow footprints. We implement an Anti Cross-infection Layout, creating physical airlocks and buffer zones between the Medical Staff Dormitory and the Isolation Wards, ensuring high density does not compromise safety.

Challenge C: Complex Medical Compliance

The Municipal Hospital project required integrating heavy medical equipment (X-Ray/Surgery) into a lightweight structure, raising concerns about radiation safety and air quality.

SOEASY move beyond standard wall panels.

SOEASY integrate Lead-lined Wall Systems and specialized Lead Doors (1200x2000mm) into the container frame to block ionizing radiation.

SOEASY install Purified Board Panels (Antibacterial) to create a hermetically sealed environment capable of sustaining Negative Pressure, meeting international Infection Control Design standards.

Scan to wechat: